Membrane Switches: A Budget-Friendly Solution for Advanced Control Systems

Membrane Switches: A Budget-Friendly Solution for Advanced Control Systems

Blog Article

Membrane Switch Modern Technology: The Secret to Trustworthy and Cost-Effective Interfaces

Membrane layer switch modern technology has emerged as an essential component in the style of interface, giving both integrity and cost-effectiveness across a diverse range of applications. Its robust building and construction makes certain resistance to ecological obstacles, while the adaptability in design enables for tailored remedies that fulfill particular sector demands. As we check out the complex advantages of membrane layer buttons, their capacity for innovation questions regarding future applications and developing trends. What does the following phase hold for this modern technology in a significantly digital landscape?

Recognizing Membrane Change Modern Technology

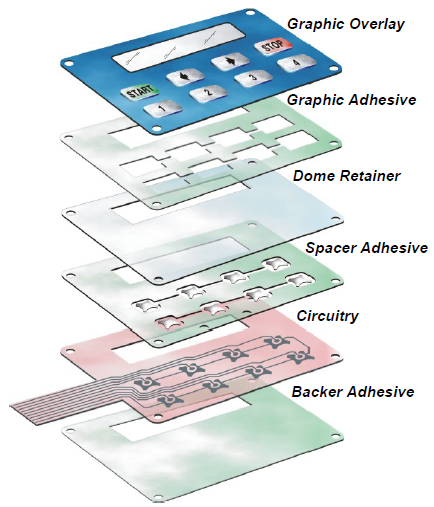

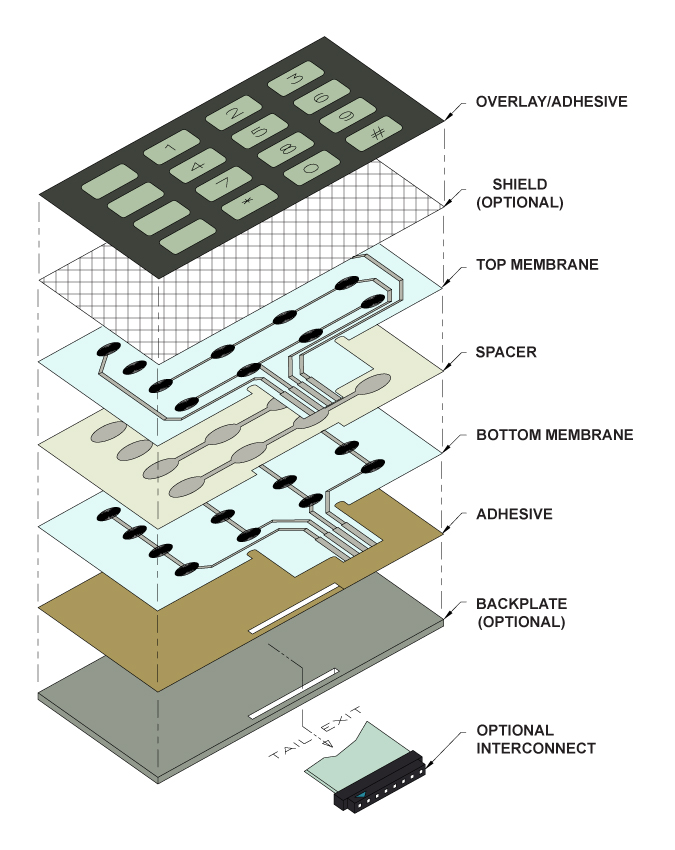

Membrane button innovation is a commonly used user interface service in numerous digital tools, supplying a smooth mix of functionality and design. This technology integrates multiple layers of materials, generally being composed of a visuals overlay, spacer layer, and a circuit layer. The visuals overlay shows the user interface components, while the spacer layer separates the circuit layer from the overlay until a user turns on a button.

When stress is used to the overlay, the circuit layer finishes the electric circuit, sending a signal to the tool. This system permits different configurations, including tactile comments and backlighting alternatives, boosting user communication. Membrane buttons are typically manufactured using durable products such as polyester or polycarbonate, guaranteeing durability and resistance to ecological factors like dampness and dust.

The versatility of membrane switches enables their application in diverse sectors, including medical gadgets, consumer electronic devices, and industrial controls. Their small design enables integration into space-constrained atmospheres, offering an efficient interface without jeopardizing visual appeal. Recognizing the details of membrane layer button technology is necessary for producers and designers seeking to develop reliable and effective human-machine interfaces.

Key Advantages of Membrane Layer Switches

While numerous user interface solutions exist, membrane changes deal unique advantages that make them a favored choice in many applications. One of the key advantages is their toughness; membrane layer buttons are designed to stand up to rough ecological conditions, including wetness, dust, and temperature variations, making certain durable efficiency. This resilience dramatically reduces the need for frequent replacements, therefore lowering general upkeep prices.

Moreover, membrane layer switches are lightweight and compact, making them ideal for applications where room is limited. Their low-profile design adds to a sleek appearance without endangering capability.

Cost-effectiveness is also a noteworthy advantage, as the production procedure for membrane switches often tends to be less costly compared to standard mechanical switches. This cost, incorporated with their dependability and convenience of installment, settings membrane layer switches over as a functional service for a large range of markets looking for reliable and reliable user interfaces.

Applications Across Different Industries

Exactly how do membrane layer switches adjust to the varied demands of various sectors? Membrane layer button innovation is significantly recognized for its flexibility, making it ideal for a variety of applications across multiple sectors. In the medical field, membrane buttons are used in analysis devices and patient surveillance tools, where their resilience and simplicity of cleansing are crucial for maintaining health criteria. The automotive industry employs these switches in dashboards and control panels, providing a structured visual while guaranteeing straightforward operation.

In customer electronics, membrane switches provide a portable service for remote controls and home devices, boosting customer experience with user-friendly design. Additionally, the commercial field leverages membrane layer switches for equipment control board, gaining from their resistance to harsh settings, such as wetness and dirt.

Army and aerospace applications additionally utilize membrane buttons for that site their integrity and capability to endure extreme conditions, guaranteeing functional performance in important circumstances. Additionally, the food and drink market takes on these switches for find more automated systems, where hygiene and simplicity of operation are paramount. Eventually, membrane layer buttons are customized to fulfill the unique demands of each industry, verifying their important role in modern technology user interfaces

Style and Customization Choices

In the realm of membrane switch modern technology, design and customization alternatives play a crucial duty in enhancing performance and user interaction. These buttons can be tailored to fulfill specific operational needs and visual preferences, making them versatile components in different applications.

One of the key modification choices is the layout of the switch itself, which can be made to suit unique interface and ergonomic factors to consider. By adjusting the shape, size, and plan of buttons, makers can create instinctive designs that help with convenience of use. In addition, the unification of different colors and visuals overlays permits branding and improved visibility, guaranteeing that customers can quickly determine features.

In addition, membrane layer switches can be engineered with various tactile responses devices, such as raised buttons or distinct clicks, to enhance the user experience. Various materials can additionally be chosen for resilience and environmental resistance, addressing factors such as wetness, temperature level changes, and chemical direct exposure.

Ultimately, the extensive layout and modification choices offered in membrane switch modern technology equip services to produce tailored solutions that not only meet practical requirements but also click here for more align with their branding and operational needs.

Future Fads in Membrane Layer Switches

As membrane button technology continues to advance, future fads are progressively concentrated on improving individual experience and incorporating sophisticated functionalities. One significant trend is the combination of touch-sensitive and capacitive technologies right into conventional membrane layer buttons. This development permits for even more instinctive interface, offering tactile comments while preserving a streamlined style.

Another arising fad is the usage of eco pleasant products, driven by the expanding demand for lasting production methods. Makers are seeking to lower their carbon footprint by using recyclable substratums and low-impact inks, aligning with worldwide sustainability objectives.

Furthermore, the increase of the Internet of Points (IoT) is motivating the unification of wise attributes into membrane switches. Boosted connectivity alternatives will make it possible for tools to communicate with each various other, enabling smooth integration right into broader systems.

Additionally, innovations in printing modern technologies, such as digital printing, are enabling for higher design flexibility and modification. This enables manufacturers to produce detailed styles and vibrant shades cost-effectively.

Final Thought

In conclusion, membrane switch technology represents a crucial development in individual interface layout, using significant advantages in toughness, modification, and cost-effectiveness. As improvements continue to arise, specifically in touch-sensitive user interfaces and lasting materials, the capacity for membrane changes to boost individual experience and functionality continues to be encouraging.

Report this page